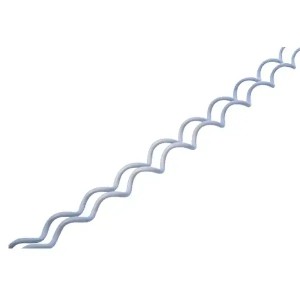

Introduce: As technology continues to advance, industries continue to seek innovative solutions to increase efficiency and productivity. One of the advances that shows great potential is the development of vibration-proof whips. This cutting-edge technology promises to revolutionize numerous industries by providing stability and precision in demanding work environments.

Improve efficiency: The vibration-proof whip uses advanced vibration reduction technology, allowing it to minimize the impact of vibration during operation. This groundbreaking development not only improves operator comfort but also significantly improves work efficiency. Industries such as construction, manufacturing and transportation that often experience excessive vibration will benefit most from this innovation.

Construction industry: In the construction world, vibration-proof whips can be a game changer. Workers often face challenges operating machines efficiently due to constant vibration. With this new technology, the risk of human error can be reduced, thereby increasing safety and productivity. The ability of whips to stabilize hand tools such as jackhammers or chisels will revolutionize the way construction projects are carried out.

Manufacturing: The manufacturing process often involves heavy machinery, causing vibrations that affect accuracy and quality. The introduction of vibration-proof whips provides a breakthrough solution. By ensuring stability during operation, the risk of errors and defects is minimized, ultimately increasing productivity and reducing manufacturing costs. The technology has the potential to transform industrial manufacturing processes and perform well in demanding environments.

Transportation: The transportation industry relies heavily on vehicles such as trucks, buses and trains. These vehicles are prone to vibration, especially when traveling at high speeds or on uneven terrain. Anti-vibration whips play a key role in ensuring a smoother, more comfortable ride for passengers. Additionally, it reduces maintenance costs by minimizing wear caused by excessive vibration, increasing component life and reducing downtime.

In conclusion: The development of vibration-proof whips, has brought broad prospects to various industries. Its ability to cancel vibrations significantly increases productivity, reduces errors and improves operator comfort. As this technology continues to mature, we can expect to witness its integration in multiple areas, revolutionizing traditional operating practices and paving the way for a more effective and efficient work environment.

Post time: Nov-09-2023