The anti-vibration whip manufacturing industry has been undergoing significant developments, marking a transformative phase in the way anti-vibration whips are designed, manufactured and used in various industrial applications. This innovative trend is gaining widespread attention and adoption for its ability to improve the safety, efficiency and durability of industrial operations, making it a top choice for construction companies, manufacturing facilities and industrial maintenance teams.

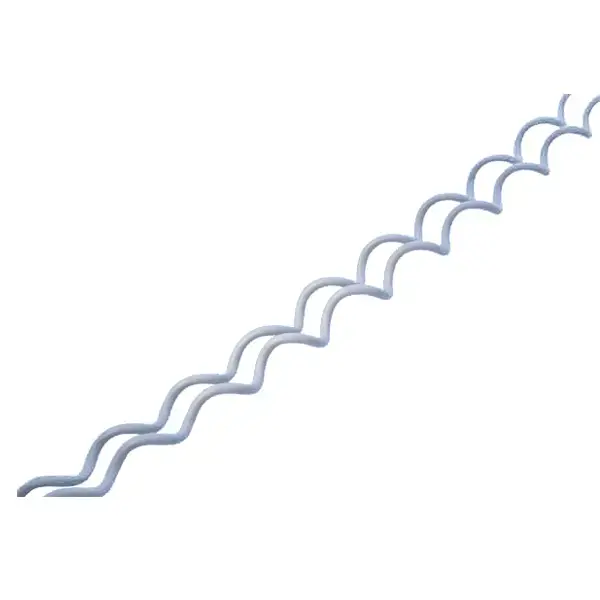

One of the key developments in the anti-vibration whip industry is the integration of advanced materials and engineering technologies to improve performance and reliability. Modern anti-vibration whips are designed using high-quality elastic materials with excellent resistance to vibration, shock and harsh environmental conditions. Additionally, these whips are engineered with precision manufacturing including reinforced handles, shock-absorbing components and durable whip ends to ensure optimal performance and longevity in demanding industrial environments.

Additionally, concerns about safety and compliance have driven the development of anti-vibration whips that comply with industry-specific regulations and safety standards. Manufacturers are increasingly ensuring that anti-vibration whips comply with recognized safety requirements, assuring industrial operators and safety regulators that the whips are designed to withstand the rigors of industrial operations while minimizing the risk of accidents and injuries. The emphasis on safety and compliance makes anti-vibration whips an important tool for safe and efficient industrial maintenance and construction activities.

Additionally, anti-vibration whips’ customizability and adaptability make them a popular choice for a variety of industrial applications and operating conditions. These whips are available in a variety of lengths, handle designs and whip end configurations to meet specific industrial maintenance and construction needs, whether for equipment maintenance, structural inspection or vibration reduction in industrial environments. This adaptability enables industrial maintenance teams and construction professionals to optimize the safety and effectiveness of their operations, solving a variety of industrial maintenance and construction challenges.

As the industry continues to make advancements in materials, safety, and customization, the future of anti-vibration whips looks promising, with the potential to further improve the safety and productivity of industrial operations in different industrial sectors.

Post time: Jun-12-2024